Production Unit 1 of JSC Belaruskali. Technical upgrading of a sylvite processing plant. Installation of a fine-fraction flotation plant.

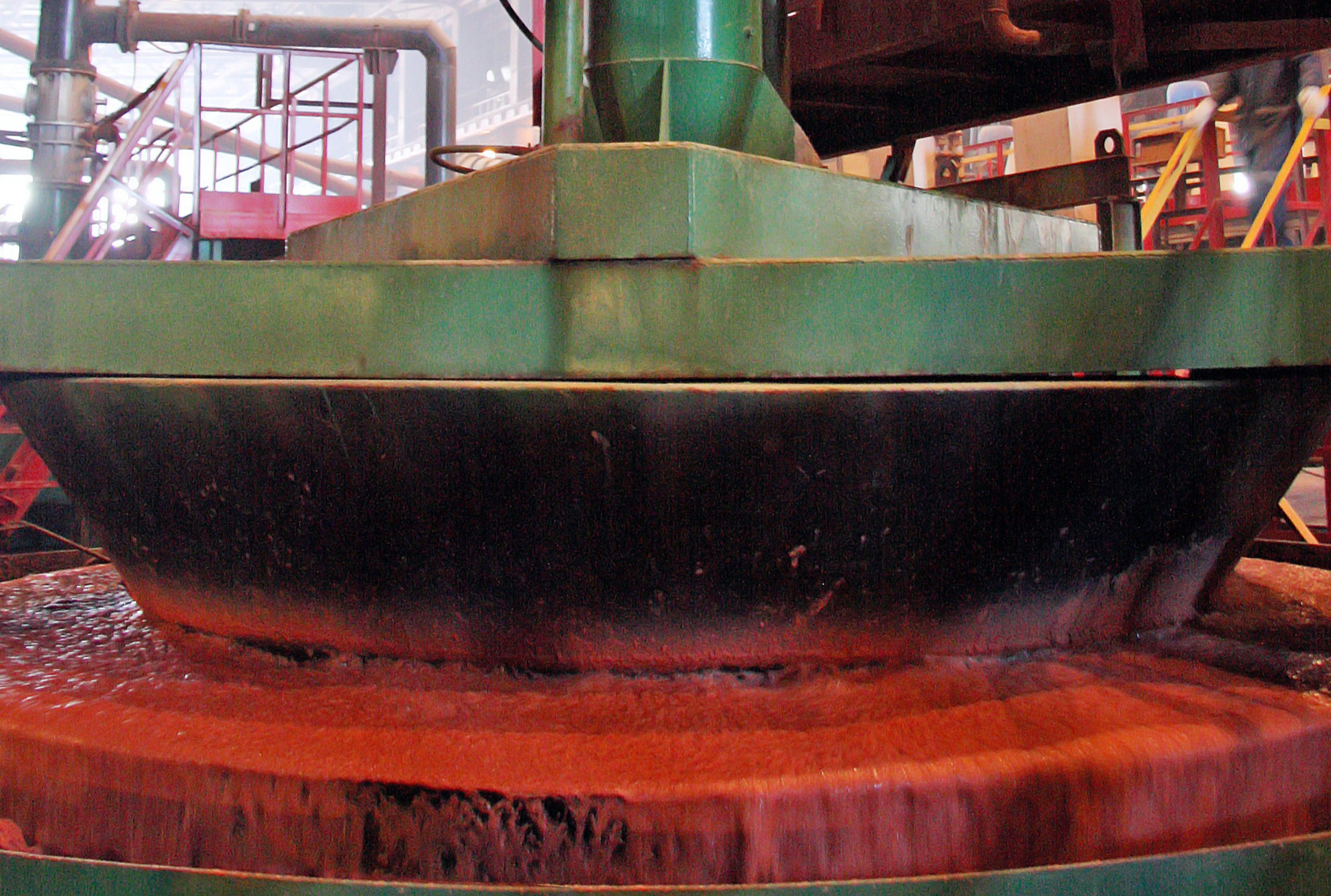

At present fine-fractin flotation of sylvite ore is carried out together with the main flotation at all the operating technological sections. Fine fractions make up to 25% of all the processed sylvite ore, which amounts to about 240 t/h in the solid residual. For reducing the amount of KCl in the tailings, increasing KCl extraction by 0.5%, increasing the quality of the concentrate and reducing loads on operating technological sections it was decided to organize fine-fraction flotation in a separate section where 50% of the extracted fine fraction could be flotated. The technological section would be based on pneumatic ejector flotation machines IMF-41 (main flotation) and IMF-35 (cleaner flotation).

Design characteristics:

In accordance with the project aimed at power consumption reduction PASSAT Holding installed flotation machines IMF-41 for the main flotation and IMF-35 for cleaner flotation. Moreover it replaced pumping units, vessels and filters. Old beams were dismantled and new beams and ceilings for supporting the equipment were installed at marks +3,800, +4,950, +5,600, +9,000, +9,950, +10,700, +13,550, +25,000.

Normative construction term was 9 months in view of double-shift work. Actual construction term made up 6 months.

As a result of the technical upgrading the customer:

Increased the capacity of flotation from 200 to 230 tons per hour

Improved the quality of the concentrate

Reduced losses with the tailings

Reduced expenses on technical maintenance of the machines

Reduced production areas twice.