Modernization of electric drive and control system of Trust Shahtospetsstroy block mobile hoists

Trust Shahtospetsstroy mobile hoists were used in shaft sinking at Belaruskali Berezovsk and Krasnoslobodsk mines. Machines electrics have been significantly worn-out. Out-of-date equipment entailed large amounts of energy during works. The Institute of mining and electrical engineering has modernized four hoists (three of them with air-spring brake actuator and another one – with hydraulic brake actuator).

A list of works carried out:

complete removal of all electrical equipment;

manufacturing and installation of the new regulated electric drive with microprocessor control system;

diagnostics, repair and adjustment of mechanical scope of hoists;

training of technological personnel.

Hoists modernization includes:

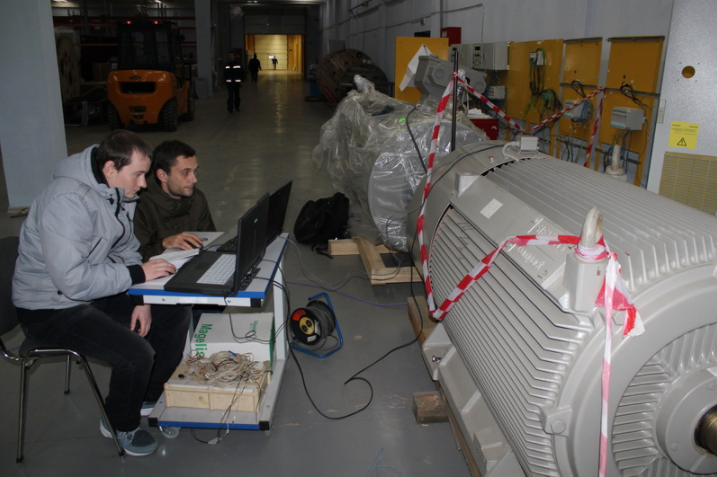

replace the existing high-voltage induction motors with wound rotor by the low-voltage induction motors with a cage rotor 690kVt power, voltage 690V; MPP25

replace rotary resistance stations, reversers and dynamic braking devices by frequency converters;

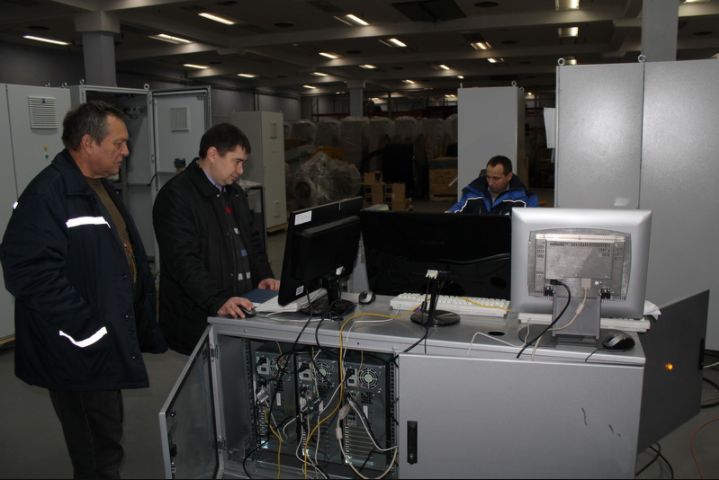

replace relay-electronic control systems and switchgears 0,4 kV by a two-channel control system based on microprocessor controllers S7 400 with periphery stations ET200, and new switchgears 0,4 kV;

replace the high-voltage switchgear KRUE-10B-60-20U2 type by small-sized complete switchgear KRU / TEL-10 kV type;

installation of dry power transformers for inverters capacity of 1250 KW, voltage 10/0,69kV, with the scheme of incorporating D/Un-11, Uk = 6%, with earthed neutral.

During the control system modernization the IGEA specialists developed electric cabinets to control main and auxiliary hoists actuators, automated machine operator workstation; installed sensors to monitor the operating parameters; developed recording and data registering equipment; implemented a bind to the power supply system and the system of the mine shaft signaling.

The modernization will allow the customer get the following technical and economic effect:

saved electric power consumed in the hoists operating during the shaft sinking, can be up to 60%;

the new control system, which includes a visualization system for hoists drivers, significantly increases the level of safety in shaft sinking.

The customer – Trust Shahtospetsstroy - will continue to use them in Petrikov mine shaft sinking.